Is your product screwed, do you have it in the bag, or is it time to consider something new?

Disclosure Statement: RoosterBio has no financial affiliation with any of the products or technologies discussed in this article. The opinions expressed here are solely intended to highlight some of the cell therapy product packaging options currently available. This article aims to illustrate many of the pros and cons of a variety of container technologies but does not constitute an endorsement or opposition to any system or company.

There are many considerations when evaluating potential final product containers for cellular therapies. “Will the product fit the given container?” is certainly the most obvious and fundamental, but it is rarely that simple. Choosing the best container for your final product can quickly go from a simple decision to a lasting problem with unintended consequences.

A good final product container should not only physically contain the product, but also provide adequate physical protection and stability of the product for the entire lifecycle of that product. This has implications in terms of temperature stability, light protection, particulate levels, and leachable and extractable materials along with simple container integrity maintenance throughout manufacturing, storage, and shipment. The given container must work in the manufacturing process and be sufficiently scalable for commercial success. The end user must be able to access the living cell product without impacting viability or potency, and can ideally achieve repeatable results with minimal effort. There may also be a need to consider the testing and quality control systems which could have different requirements than those of the manufacturing process or end user. Many products also require certain information to be readily available on the label or attached to the product. This can create added difficulties with smaller containers, which can also impact marketing—and those concerns should not be overlooked.

There are often no right or wrong decisions when it comes to choosing a final product container, but there are always tradeoffs, pros, and cons. Here we discuss the three most common types of containers used throughout the biotech field, and specifically for cell therapy applications: (i) screw top vials, (ii) bags, and (iii) sealed or semi-closed vials. Note that this article will avoid discussing glass vials specifically. There may be instances where a glass vial is required for a lyophilized product—but despite some glass vials being capable of surviving cryogenic temperatures—there is almost always an alternative non-glass product with superior physical attributes.

Screw Top Cryo Vials

This class of container is almost certainly the most common for cryopreserved cells in cell culture applications, and for good reason. These types of vials have existed long before the rise of regenerative medicine and are readily available to anyone in nearly any market. They are straightforward to incorporate into a manufacturing process, easy to understand for the end-user, and typically work well for testing and analytical applications. The multitude of available options can make choosing the best vial seem a bit daunting, but many xeno-free options exist, most can withstand cryogenic temperatures for long periods of time, and there are options for automated or semi-automated filling processes.

Despite the overall ease of use, there are several reasons to consider alternative containers, especially when considering the requirements of cellular therapies. While scaling up the filling process for screw top vials is possible, it can be labor-intensive and, in some cases, require nearly as much financial and technical investment as other container technologies. Possibly the biggest detractor for the screw top vial may be its most fundamental component, the screw top cap itself. The very nature of a screwed-on cap means these containers will never be a closed system. They must be open and exposed to the surrounding environment when being filled in the manufacturing process, and next when their contents are accessed by the end-user. This typically results in the requirement for processing in a biological safety cabinet (BSC) or similar isolated environment, as well as handling by well-trained personnel who exceed a certain minimal threshold of manual dexterity. While this rarely presents a problem for small-scale manufacturing or most testing organizations, it can add complexity and contamination risk at clinical sites, hospitals, and ultimately for patients. Additionally, screw top vials are somewhat limited in the maximum practical volumes that they can hold. For volumes up to approximately 2 mL, the off-the-shelf options are extensive; however, those options shrink quickly when looking for larger capacity vials and there are very few off-the-shelf screw top vials available that exceed 5 mL in size. The generally small size of these types of containers can also present labeling challenges. Often the small curved surface does not allow for all the required information to be printed on the vial and/or be easily legible, particularly when retrieved from cryostorage. These space constrictions can be overcome with expandable labels, packaging, barcodes, and product inserts, but these solutions all come with added complexity and often obscure the view of the final product within.

Despite the overall ease of use, there are several reasons to consider alternative containers, especially when considering the requirements of cellular therapies. While scaling up the filling process for screw top vials is possible, it can be labor-intensive and, in some cases, require nearly as much financial and technical investment as other container technologies. Possibly the biggest detractor for the screw top vial may be its most fundamental component, the screw top cap itself. The very nature of a screwed-on cap means these containers will never be a closed system. They must be open and exposed to the surrounding environment when being filled in the manufacturing process, and next when their contents are accessed by the end-user. This typically results in the requirement for processing in a biological safety cabinet (BSC) or similar isolated environment, as well as handling by well-trained personnel who exceed a certain minimal threshold of manual dexterity. While this rarely presents a problem for small-scale manufacturing or most testing organizations, it can add complexity and contamination risk at clinical sites, hospitals, and ultimately for patients. Additionally, screw top vials are somewhat limited in the maximum practical volumes that they can hold. For volumes up to approximately 2 mL, the off-the-shelf options are extensive; however, those options shrink quickly when looking for larger capacity vials and there are very few off-the-shelf screw top vials available that exceed 5 mL in size. The generally small size of these types of containers can also present labeling challenges. Often the small curved surface does not allow for all the required information to be printed on the vial and/or be easily legible, particularly when retrieved from cryostorage. These space constrictions can be overcome with expandable labels, packaging, barcodes, and product inserts, but these solutions all come with added complexity and often obscure the view of the final product within.

Bags

This class of container may not be as ubiquitous as the screw top vial, but bagged cell therapy products have existed since the earliest days of the industry. A bagged final product can be produced in a completely closed manufacturing process, and in an industry prone to viewing the process as the product, this can be invaluable.

A bagged product also has the potential to be sterile welded to another bag or cell culture container allowing for a completely closed transfer process. In a manufacturing environment, this can be extremely beneficial and reduce or eliminate the need for a BSC or similarly controlled environment. With a variety of final product bags available off-the-shelf, and often customizable, finding an appropriate solution for almost any volume is possible. This can make bagged final products particularly appealing for large volume but low number manufacturing processes. Bags can be exceptionally valuable when considering the starting materials for a large-scale manufacturing process that is already using “single-use” materials and is otherwise a closed system. Additionally, often a nice feature of bagged products is the increased space for labeling. Many bags feature a pocket that can contain a label or additional information that will not fall off in cryogenic storage and can even be printed double-sided and does not interfere with the visual assessment of the product itself.

That said, choosing to put your final product in a bag is not without downsides. Many bags are rated for cryogenic storage and do hold up very well, however they are not often as durable as more rigid containers. Typically, some sort of case or overwrap is recommended for added structural security during storage at liquid nitrogen temperatures. This can add complexity to a manufacturing process that is almost always innately more difficult and labor-intensive for bags than other types of containers. The process of filling a sealed bag in a closed single-use system can be uniquely challenging. The filling process typically involves welding tubing along with pumps or syringes, and excess air must be removed from the system. Sterile tubing welders are a viable option for assembling a filling line, but if the filling process requires every bag to be welded and sealed before another bag can be filled that will create a significant bottleneck in terms of maximum throughput. To some extent, throughput issues can be ameliorated with simpler and faster connections or manifold systems. However, often a simple solution is not desirable. For example, attaching and detaching a Luer lock is much faster than welding and sealing, but negates some of the closed system advantages. Similarly, a manifold allowing many bags to be filled at once results in more loss of final product in the system as well as complicating the process of priming and ensuring precise control of fill volume. Ultimately, despite their advantages, bagged final products are typically more challenging to scale up, and lot sizes will generally be capped at no more than 150-200 product bags in a single manufacturing run.

That said, choosing to put your final product in a bag is not without downsides. Many bags are rated for cryogenic storage and do hold up very well, however they are not often as durable as more rigid containers. Typically, some sort of case or overwrap is recommended for added structural security during storage at liquid nitrogen temperatures. This can add complexity to a manufacturing process that is almost always innately more difficult and labor-intensive for bags than other types of containers. The process of filling a sealed bag in a closed single-use system can be uniquely challenging. The filling process typically involves welding tubing along with pumps or syringes, and excess air must be removed from the system. Sterile tubing welders are a viable option for assembling a filling line, but if the filling process requires every bag to be welded and sealed before another bag can be filled that will create a significant bottleneck in terms of maximum throughput. To some extent, throughput issues can be ameliorated with simpler and faster connections or manifold systems. However, often a simple solution is not desirable. For example, attaching and detaching a Luer lock is much faster than welding and sealing, but negates some of the closed system advantages. Similarly, a manifold allowing many bags to be filled at once results in more loss of final product in the system as well as complicating the process of priming and ensuring precise control of fill volume. Ultimately, despite their advantages, bagged final products are typically more challenging to scale up, and lot sizes will generally be capped at no more than 150-200 product bags in a single manufacturing run.

Sealed or Semi-Closed Vials

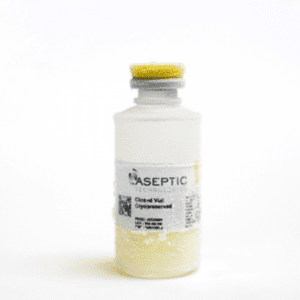

In this section, we will discuss containers that offer some of the scalability of screw top vials but also some of the closed system advantages of bags. Often these containers are filled using needles, Luer fittings, or similar connections but also incorporate ridged elements that enhance container integrity. Specifically, we will be discussing the AT-Closed Vials® produced by Aseptic Technologies and the CellSeal® closed-system cryogenic vials by Sexton Biotechnologies.

Though vials capped with a pierceable septum are not a new technology in themselves, the ability to both fill and dispense from AT-Closed Vials without removing that septum does offer some unique advantages. When being filled, a special needle allows air to escape while the cell suspension product is introduced, thus preventing over-pressurization. As the needle is removed, the elastomeric material of the septum closes around the needle, preventing any further interaction with the external environment or release of the liquid product within. The integrity of the septum is then restored using a specially designed laser that fuses the elastomeric material without impacting product quality. The entire stopper is then protected by a tight-fitting plastic cap. Filling a small number of vials can be accomplished with relatively minimal equipment, and the same technology can be easily scaled up to commercially relevant levels (eg. 1000s of vials per lot) with automated filling systems.

The AT-vials come in a variety of sizes from 1 mL up to 50 mL, so volume considerations are rarely an issue. AT-Closed Vials® are compatible with cryogenic temperatures, and all but the largest vails can fit upright into standard cryobox configurations for storage and shipment, though additional custom options are available. When combined with the AT-Adapt™ vented vial access device, removing the contents of any given vial is as easy as attaching a syringe to the Luer and filling the syringe. No needles are required, and the incorporated air vent prevents any issues with over or under pressure. Additionally, this configuration creates options for connections to tubing or other similar components using a Luer connection.

Aseptic Technologies has also done extensive work to validate these vials, including leachable and extractable studies along with registering Drug Master Files (DMF) with the Food and Drug Administration (FDA). All these factors make work with AT-Closed Vials® attractive, particularly for late-stage development and commercial applications; nevertheless, there are downsides. The initial investment in the technology and equipment to reliably work with these vials, even at small scales, is likely higher than any of the container options previously discussed. It is possible to fill vials using ordinary syringes and needles, but this is a slow and cumbersome process. Also, without the purchase of laser sealing equipment, it is not possible to realize the maximum benefit of these vials. It should also be noted that filling these vials in a manufacturing setting will still require the filling equipment to be situated in a controlled environment. Though the septum provides a reasonably aseptic way to remove material, comparable to existing injectable products, the needle used for filling is exposed to the external environment throughout the filing process. The basic entry-level equipment easily fits into most standard-size BSCs, but higher throughput and automated filling equipment will require more customized equipment for isolating this part of the process.

Aseptic Technologies has also done extensive work to validate these vials, including leachable and extractable studies along with registering Drug Master Files (DMF) with the Food and Drug Administration (FDA). All these factors make work with AT-Closed Vials® attractive, particularly for late-stage development and commercial applications; nevertheless, there are downsides. The initial investment in the technology and equipment to reliably work with these vials, even at small scales, is likely higher than any of the container options previously discussed. It is possible to fill vials using ordinary syringes and needles, but this is a slow and cumbersome process. Also, without the purchase of laser sealing equipment, it is not possible to realize the maximum benefit of these vials. It should also be noted that filling these vials in a manufacturing setting will still require the filling equipment to be situated in a controlled environment. Though the septum provides a reasonably aseptic way to remove material, comparable to existing injectable products, the needle used for filling is exposed to the external environment throughout the filing process. The basic entry-level equipment easily fits into most standard-size BSCs, but higher throughput and automated filling equipment will require more customized equipment for isolating this part of the process.

The CellSeal vials produced by Sexton Biotechnologies offer another example of sealed or semi-close containers. These vials come in 2 mL and 5 mL sizes and feature a ridged vial with a protected septum on one end and a sealable section of tubing terminating in a needleless Luer fitting on the opposite end. There is also a vent containing a microbial barrier (which can prevent pressure issues), or be sealed off for enhanced vessel integrity. This configuration accommodates a variety of manual filling options including syringes, pipettes, and needleless Luer fittings. Once filled, the tubing can be sealed using a radio frequency sealer, creating a completely closed and very secure container. Even after being sealed, similar methods can be used to remove the product. The protective cover can be removed from the bottom of the vial allowing access to the septum, and the vent can be re-opened by cutting away the seal. This facilitates easy removal of the product with a needle, but Sexton has also created a vial adaptor that can be attached over this septum creating a needleless Luer fitting. This allows syringes or tubing to be connected for needle-free removal of material. Sexton has also created a wide variety of accessories, including snap-on vial markers, freezing containers, an automated thawing device, storage boxes, and freezer racks that make them easier to incorporate into existing laboratory systems. Additionally, the manufacturer has conducted extractable/leachable studies with good results and has a US FDA Master File in place that can be made available to support customers.

Potentially one of the biggest advantages of the CellSeal® system is in regard to scalability. Sexton Biologics currently has developed two devices that are capable of filling these vials in an automated fashion. The Signate CT-5TM is a small-scale system capable of formulating up to 1.5 L of product and dispensing that product into CellSeal® vials or compatible bags. The small footprint and flexible design should lend themselves well to a development lab or small-scale GMP operations. For larger-scale processes, there is the AF-500 system. This system, while still designed to fit in a standard biological safety cabinet, is capable of filling up 400 vials per hour. Ultimately, the CellSeal® system is still a relative newcomer in the vast array of final product container options. The limited vial options might be prohibitive to some products, and the generally taller profile may require modification to existing storage and shipping systems. That said, Sexton Biotechnologies has thought of solutions to many of the potential challenges in working with these unique containers, and they could be an excellent solution for your product.

Summary

Whether you are designing a new cell therapy product from the ground up or looking for a new container to provide additional capability to your existing product, there are many options to consider. Screw top vials are often the simplest solution and the fastest to implement, single-use bags have advantages for completely closed systems, and systems like AT-Closed Vials® and CellSeal® vials provide increased flexibility and scalability. For whatever your product or scale, one of these containers can likely suit your needs.

Further Reading

Aseptic Technologies: AT-Closed Vial®, https://www.aseptictech.com/products/closed-vialr-0

Sexton Biotechnologies: CellSeal® Vials, https://sextonbio.com/product/cellseal-closed-system-cryogenic-vials/

FDA: Cellular & Gene Therapy Guidance, https://www.fda.gov/vaccines-blood-biologics/biologics-guidances/cellular-gene-therapy-guidances

References

“AT-Closed Vial® Range” Aseptic Technologies, 2020, www.aseptictech.com/products/closed-vialr-0.

“CellSeal® Closed-System Cryogenic Vials.” Sexton Biotechnologies, 2020, sextonbio.com/product/cellseal-closed-system-cryogenic-vials/.

“CellSeal® Vial Adapter.” Product Instructions, Sexton Biotechnologies, 2020, sextonbio.com/resources2/.