RoosterReplenish™-MSC-XF

An MSC-specific, xeno-free (XF) bioreactor feed

Engineered to clear out costly media exchanges, taking media productivity to a whole new level – and making you an MSC bioreactor expert, overnight.

Recommended Products

Overview

Contact your RoosterBio representative for information on cGMP formats of RoosterReplenish-MSC.

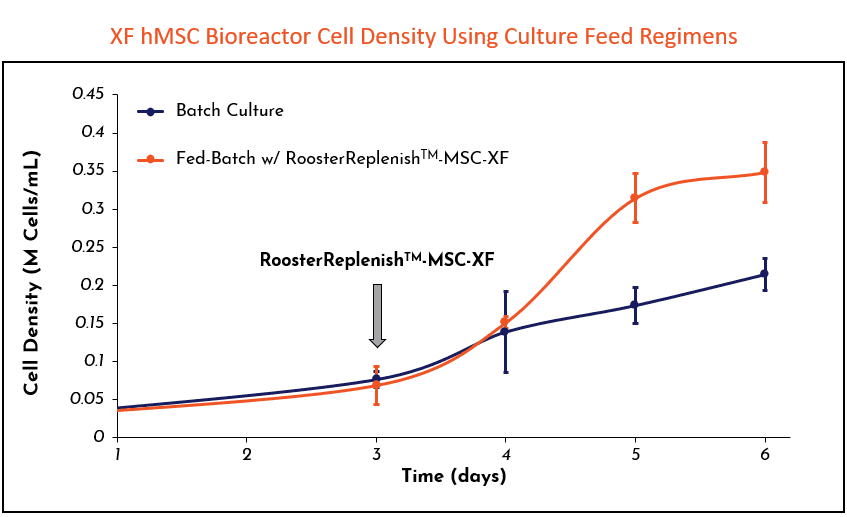

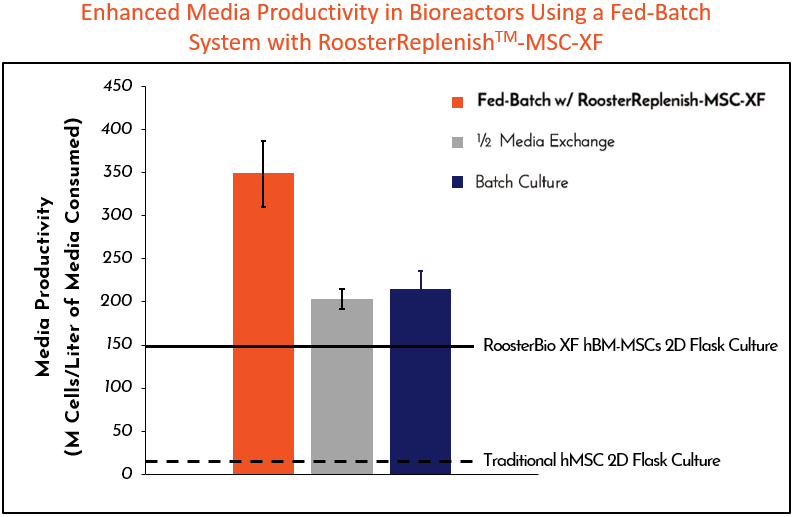

RoosterReplenishTM-MSC-XF is a concentrated bioreactor feed for use in a fed-batch bioreactor process, enhancing media productivity to drive a radically cost-effective process that is less labor-intensive in small- and large-scale expansions of hMSCs in 3D bioreactors. RoosterReplenishTM-MSC-XF is designed to achieve high cell growth in microcarrier-based suspension cultures when paired with our xeno-free (XF) hMSCs (derived from multiple tissue types) and paired bioprocess media (RoosterNourish™-MSC-XF). Using RoosterNourish™-MSC-XF and RoosterReplenishTM-MSC-XF in a fed-batch system not only increases culture yield, it also minimizes the time required for media preparation, eliminates media exchange, and reduces the contamination risk associated with in-process manipulation. RoosterReplenishTM-MSC-XF boosts media productivity (millions of cells produced per Liter of media consumed) by up to 70%. Each 10 mL bottle of RoosterReplenishTM-MSC-XF can be used to supplement 500 mL of RoosterNourishTM-MSC-XF, with analogous version available for cGMP manufacturing.

Product Features

- Enables a fed-batch suspension hMSC culture process. This feed is added on Day 3 of bioreactor culture to provide additional mitogenic factors to the culture.

- Streamlines culture processes & reduces processing time and labor.

- Minimizes media usage, reducing total cost associated with hMSC culture scale-up, and boosts media productivity by up to 70%.

- Maintains stable nutrient and waste bio-profiles through 7 days of culture; comparable to batch culture.

- Incorporates translation-friendly processes and components into your workflow.

- Eliminates the media efficiency optimization step in small- and large-scale stem/stromal cell biomanufacturing process development – shortening development timelines, increasing cell lot size, and streamlining biomanufacturing steps for those on the path to commercial scale production.

- Mitigates risk of contamination by minimizing in-process culture manipulation.

Intended Use: Research Use Only

Login to search Certificates of Analysis and Quality Control Briefs.